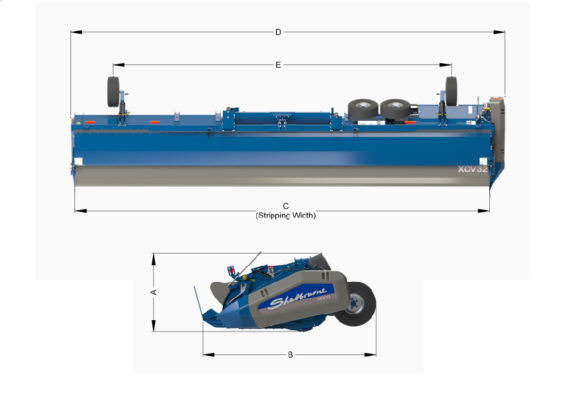

The XCV range is available in 3 widths:

- XCV32 32ft / 9.6m

- XCV36 36ft / 10.8m

- XCV42 42ft / 12.6m

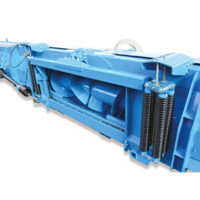

The heavy duty variable speed drive system is suited for harvesting cereal grains which allows the operator to adjust the stripping rotor speed from the comfort of the cab throughout the day.

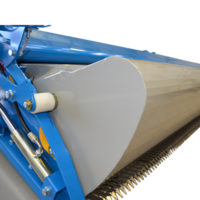

The machine incorporates 3 stripping rotor’s with two equally spaced division plates. this means that the rotors are shorter and are able to operate smoother with greater reliability.

The sprung loaded adapter plate system which when coupled to the spring loaded gauge wheels enables the header to follow the ground contours.

Central mounted to be compatible with modern controlled traffic operations.