If you have questions or require advice about the 8000 Series Hedge Cutter, or any of our other products, then contact us today.

The 8000 Series hedge and verge cutter range has been designed with professional users in mind, it is a heavy duty range incorporating a large number of standard features aimed at the high hour user.

The 8060T has telescopic reach giving the machine a retracted reach of 4.80M which can be extended to its maximum reach of 6.0M. This then gives the trimmer a compact design without compromise to its reach.

Key design elements have been developed in cooperation with owners and users of the 8000 series to give this model a heavy duty build to suit the high hour operator.

| 70HP Hydraulic System |

| S-Touch Compact Joystick Control System |

| GP1200 1.2m Belt Drive Head (LH) |

| Oil Cooler with Auto Reversing Fan |

| Head Float |

| Twin Accumulator Arm Float |

| Auto-Reset Break Back |

| 102 Degree Slew |

| Bolted Adjustable Head Roller |

| Parallel Arm Geometry |

| LED Road Lights & 180 Degree Strobe |

| Parking Stands / Forklift Shoes |

| Transport Safety Stop |

The 8070T has telescopic reach giving the machine a retracted reach of 5.50M which can be extended to its maximum reach of 7.0M. This then gives the trimmer a compact design without compromise to its reach.

Key design elements have been developed in cooperation with owners and users of the 8000 series to give this model a heavy duty build to suit the high hour operator.

| 70HP Hydraulic System |

| S-Touch Compact Joystick Control System |

| GP1200 1.2m Belt Drive Head (LH) |

| Oil Cooler with Auto Reversing Fan |

| Head Float |

| Twin Accumulator Arm Float |

| Auto-Reset Break Back |

| 102 Degree Slew |

| Bolted Adjustable Head Roller |

| Parallel Arm Geometry |

| LED Road Lights & 180 Degree Strobe |

| Parking Stands / Forklift Shoes |

| Transport Safety Stop |

The 8080T has telescopic reach giving the machine a retracted reach of 6.20M which can be extended to its maximum reach of 8.0M. This then gives the trimmer a compact design without compromise to its reach.

Key design elements have been developed in cooperation with owners and users of the 8000 series to give this model a heavy duty build to suit the high hour operator.

| 70HP Hydraulic System |

| S-Touch Compact Joystick Control System |

| GP1200 1.2m Belt Drive Head (LH) |

| Oil Cooler with Auto Reversing Fan |

| Head Float |

| Twin Accumulator Arm Float |

| Auto-Reset Break Back |

| 102 Degree Slew |

| Bolted Adjustable Head Roller |

| Parallel Arm Geometry |

| LED Road Lights & 180 Degree Strobe |

| Parking Stands / Forklift Shoes |

| Transport Safety Stop |

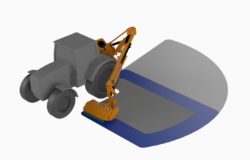

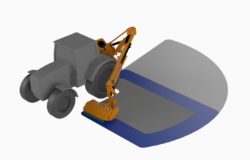

The 8065VFRT has telescopic reach giving the machine a retracted reach of 5.60M which can be extended to its maximum reach of 6.50M. This then gives the trimmer a compact design without compromise to its reach.

The variable forward reach gives the machine forward reach of up to 2.0m to improve visibility and operator comfort. Rearward reach of 1.30M enables the arm to go behind the tractor wheel to enable operation in restricted areas.

| 70HP Hydraulic System |

| S-Touch Compact Joystick Control System |

| GP1200 1.2m Belt Drive Head (LH) |

| Oil Cooler with Auto Reversing Fan |

| Head Float |

| Twin Accumulator Arm Float |

| Auto-Reset Break Back |

| 102 Degree Slew |

| Bolted Adjustable Head Roller |

| Parallel Arm Geometry |

| LED Road Lights & 180 Degree Strobe |

| Parking Stands / Forklift Shoes |

| Transport Safety Stop |

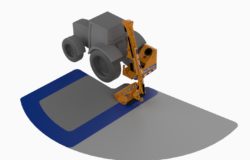

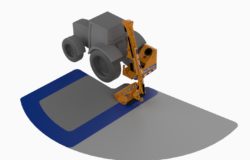

The 8075VFRT has telescopic reach giving the machine a retracted reach of 6.20M which can be extended to its maximum reach of 7.50M. This then gives the trimmer a compact design without compromise to its reach.

The variable forward reach gives the machine forward reach of up to 2.50m to improve visibility and operator comfort. Rearward reach of 1.60M enables the arm to go behind the tractor wheel to enable operation in restricted areas.

| 70HP Hydraulic System |

| S-Touch Compact Joystick Control System |

| GP1200 1.2m Belt Drive Head (LH) |

| Oil Cooler with Auto Reversing Fan |

| Head Float |

| Twin Accumulator Arm Float |

| Auto-Reset Break Back |

| 102 Degree Slew |

| Bolted Adjustable Head Roller |

| Parallel Arm Geometry |

| LED Road Lights & 180 Degree Strobe |

| Parking Stands / Forklift Shoes |

| Transport Safety Stop |

GP1200 (1.2m) General Purpose head suitable for grass or multi-year hedge growth. Standard on all 7000 & 8000 trimmers.

Options:

| Cutting Width 1.2m |

| Low Profile |

| Double Skinned |

| Rotor Diameter 120mm |

| Roller Diameter 125mm |

| Twin Vee Drive (LH Only) |

| Quick Hitch Fixed Mounting |

| Double Spiral Flail Pattern |

| 24 x Drop Forged Flails |

| T or Competition Flails |

| Snag Free Corners / Guards |

| Weight - 360Kg |

GP1500 (1.5m) General Purpose head suitable for grass or multi-year hedge growth. Optional head on all 7000 & 8000 trimmers.

Options:

| Cutting Width 1.5m |

| Low Profile |

| Double Skinned |

| Rotor Diameter 120mm |

| Roller Diameter 125mm |

| Twin Vee Drive |

| 50mm Rotor Bearing |

| Fixed Mounting |

| Double Spiral Flail Pattern |

| 30 x Drop Forged Flails |

| T or Competition Flails |

| Weight - 400Kg |

The HC 1200 (1.2m) flail head is a high capacity head for single pass cutting and is suitable for 7000 & 8000 Series trimmers.

Options:

| Cutting Width 1.2m |

| Sleek Design |

| Double Skinned |

| Ultra Heavy Duty |

| Rotor Diameter 150mm |

| Roller Diameter 125mm |

| Twin Vee Drive |

| 60mm Rotor Bearing |

| Fixed Mounting |

| Double Spiral Flail Pattern |

| 30 x Drop Forged Flails |

| T or Competition Flails |

| Weight - 425Kg |

The HC 1600 (1.6m) flail head is a high capacity head for single pass cutting and is suitable for 7000 & 8000 Series trimmers.

Options:

| Cutting Width 1.6m |

| Sleek Design |

| Double Skinned |

| Ultra Heavy Duty |

| Rotor Diameter 150mm |

| Roller Diameter 125mm |

| Twin Vee Drive |

| 60mm Rotor Bearing |

| Fixed Mounting |

| Double Spiral Flail Pattern |

| 36 x Drop Forged Flails |

| T or Competition Flails |

| Weight - 500Kg |

The S-Touch Compact joystick is the standard control system for the 8000 Series trimmer.

The main features include a user friendly 6″ touch screen display and is used for the functions not controlled by the joystick, the screen is also used to adjust settings for the joystick to suit the preference’s of the individual operator.

The compact joystick feature 4 proportional services and can be programmed to suit the individual operator. (Lift, Reach, Head Angle & Slew)

| Compact Joystick |

| Head Angling Side Rocker & Slew Ring at Base |

| 4 x Proportional Services |

| 6" Touch Screen Display |

| Hedge / Verge Mode |

| Electric Start Bi-Direction Rotor |

| Auto Break Back / Reset |

| Hour Counter |

| Easy Mount Seat Bracket |

| Multi-Position adjustment for Armrest / Screen |

| Gas strut for Easy Raise / Lower |

The S-Touch Max control system is an optional control for all 8000 Series trimmers.

The large multi function joystick offers maximum control to the operator

The user friendly 6″ touch screen display is used for the functions not controlled by the joystick, the screen is also used to adjust settings for the joystick to suit the preference’s of the individual operator.

| Large Multi Function Joystick |

| Rear Head Angle Rocker switch |

| Front Mounted Slew Rocker switch |

| 3 x Multi Function "Hot Keys" |

| 4 x Proportional Services |

| 6" Touch Screen Display |

| Hedge / Verge Mode |

| Electric Start Bi-Direction Rotor |

| Auto Break Back / Reset |

| Hour Counter |

| Easy Mount Seat Bracket |

| Multi-Position adjustment for Armrest / Screen |

| Gas strut for Easy Raise / Lower |

The larger oil tank helps dissipate heat and also provides additional ballast.

The 70hp system runs with high oil pressure with a low flow rate which equates to constant power to the flail.

Larger pins provide extra strength & with the additional surface area it reduces wear to the bushes.

The S-Touch Compact is the standard control with a compact joystick and 6" touch screen.

This provides additional cooling. There is also an auto reverse function which self cleans.

An additional screen is added to enable cleaning on site without the need for compressed air

This provides a safety stop whilst in transport and protection to the tractor cab.

Full LED lights provide longevity and the 180 degree strobe provides additional visibility to oncoming traffic

Providing extra storage for tools etc that you may require when working on site

This helps reduce the overall transport width

This two separate accumulator bottles can be run together or individually for extra adjustment to the arm float

S-Touch Head Memory

Automatically maintains a pre-set head angle.

S-Touch Head Memory

Automatically maintains a pre-set head angle. Axle Mounting Sub Frame

This detachable frame connects the trimmer to the axle brackets on the tractor. It connects to the trimmer main frame using two pins

Read more

Axle Mounting Sub Frame

This detachable frame connects the trimmer to the axle brackets on the tractor. It connects to the trimmer main frame using two pins

Read more

Axle Brackets

A range of axle brackets are available to fit most modern tractors

Read more

Axle Brackets

A range of axle brackets are available to fit most modern tractors

Read more

Hydraulic Roller

This allows the position of the head roller to be controlled hydraulically using the tractors spool valve

Read more

Hydraulic Roller

This allows the position of the head roller to be controlled hydraulically using the tractors spool valve

Read more

Hydraulic Nose

Hydraulic nose controlled via the tractor spool valve.

Read more

Hydraulic Nose

Hydraulic nose controlled via the tractor spool valve.

Read more

Narrow Lane Bracket

This enables the operator to tilt the head hydraulically using a tractor spool valve to enable vertical hedge side trimming in restricted areas

Narrow Lane Bracket

This enables the operator to tilt the head hydraulically using a tractor spool valve to enable vertical hedge side trimming in restricted areas 8000 Series Highway Kit

This incorporates a reflective chevron graphics package as well as a magnetic arrow for maximum highway visibility

Read more

8000 Series Highway Kit

This incorporates a reflective chevron graphics package as well as a magnetic arrow for maximum highway visibility

Read more

Debris Blower

A tractor spool valve operated hydraulic fan used for blowing hedge cuttings off of a hard smooth surface

Read more

Debris Blower

A tractor spool valve operated hydraulic fan used for blowing hedge cuttings off of a hard smooth surface

Read more

85 HP High Power Hydraulic System

Recommended for use where greater workrates are required in larger growth, available with either 540rpm or 800rpm pto input

Read more

85 HP High Power Hydraulic System

Recommended for use where greater workrates are required in larger growth, available with either 540rpm or 800rpm pto input

Read more

Verge Head Kit

Incorporates re-enforced hardened steel skid and larger 6” diameter roller

Read more

Verge Head Kit

Incorporates re-enforced hardened steel skid and larger 6” diameter roller

Read more

GP 1500 Flail Head

Available in lieu of the standard GP1200 1.2m flail head, the GP1500 1.5m head features 30 flails.

GP 1500 Flail Head

Available in lieu of the standard GP1200 1.2m flail head, the GP1500 1.5m head features 30 flails. HC 1200 & HC 1600 Flail Head

Available in lieu of the standard GP1200 1.2m flail head, the HC1200 1.2m or HC1600 1.6m.

HC 1200 & HC 1600 Flail Head

Available in lieu of the standard GP1200 1.2m flail head, the HC1200 1.2m or HC1600 1.6m.

If you have questions or require advice about the 8000 Series Hedge Cutter, or any of our other products, then contact us today.

| Technical Specifications | 8060 T | 8070 T | 8080 T | 8065 VFRT | 8075 VFRT |

|---|---|---|---|---|---|

| Controls | |||||

| S-Touch Compact | Standard | Standard | Standard | Standard | Standard |

| S-Touch Max | Optional | Optional | Optional | Optional | Optional |

| Hydraulics | |||||

| Oil Capacity | 230litres | 230litres | 230litres | 230litres | 230litres |

| Independent Hydraulics | Standard | Standard | Standard | Standard | Standard |

| Oil Cooler | Standard | Standard | Standard | Standard | Standard |

| Arm Features | |||||

| Parallel Boom Geometry | Standard | Standard | Standard | Standard | Standard |

| Boom Type | Telescopic | Telescopic | Telescopic | VFR / Tele | VFR / Tele |

| Hydraulic Slew | 102deg | 102deg | 102deg | 102deg | 102deg |

| Arm Break Back | Standard | Standard | Standard | Standard | Standard |

| Head Float | Standard | Standard | Standard | Standard | Standard |

| Arm Float | Standard | Standard | Standard | Standard | Standard |

| Flailhead Features | |||||

| GP1200 1.2m LH Drive | Standard | Standard | Standard | Standard | Standard |

| Twin 'v' Belt Head System | Standard | Standard | Standard | Standard | Standard |

| Drive System flow | 100 l/min | 100 l/min | 100 l/min | 100 l/min | 100 l/min |

| Drive System Pressure | 275 bar | 275 bar | 275 bar | 275 bar | 275 bar |

| Head Angling | 250deg | 250deg | 250deg | 250deg | 250deg |

| Roller Diameter | 125mm | 125mm | 125mm | 125mm | 125mm |

| Hydraulically Adjustable Roller | Optional | Optional | Optional | Optional | Optional |

| Weights | |||||

| Machine Weight inc Head & Oil | 2050kg | 2100kg | 2150kg | 2200kg | 2250kg |

| Min Tractor Weight | 5500kg | 5500kg | 5500kg | 5500kg | 5500kg |

| Min Tractor | 130HP | 130HP | 130HP | 130HP | 130HP |

| Mounting System | |||||

| 4pt Mounting | Optional* | Optional* | Optional* | Optional* | Optional* |

| Axle Mounting | Recommended | Recommended | Recommended | Recommended | Recommended |

| Accessories | |||||

| LED Road Lights | Standard | Standard | Standard | Standard | Standard |

| 180 deg Strobe LED | Standard | Standard | Standard | Standard | Standard |

|

Warning - It is the end user’s responsibility to ensure that the trimmer does not exceed the tractor OEM’s (original equipment manufacturer) specification for implement mounting and hitch capability and that the installation is technically appropriate based on the weight and size of the tractor and its implement attachment system.

* Owing to the size and weight of the 8000 series it is recommended that customers mount the trimmers using an axle mounting system. 4 point linkage mounting must only be used on tractors with suitable linkage mounting points and even then, Shelbourne Reynolds recommends that axle mounting is used for improved strength where possible. 8000 Series trimmers can become detached if used inappropriately with the 4 point linkage mount. |

|||||

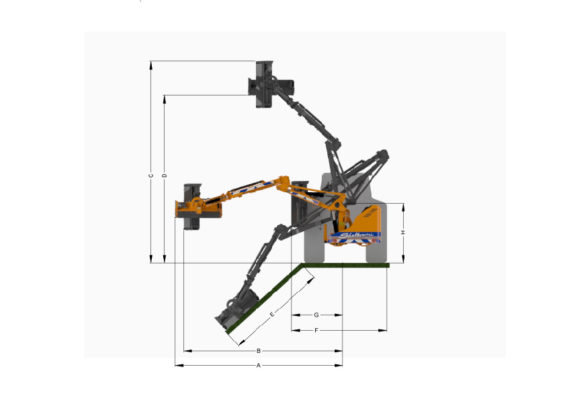

| REACH DIMENSIONS | 8060T | 8070T | 8080T | |||

|---|---|---|---|---|---|---|

| Retracted | Extended | Retracted | Extended | Retracted | Extended | |

| Max reach (A) head horizontal | 4.90mt | 6.03mt | 5.56mt | 6.98mt | 6.26mt | 8.02mt |

| Max reach (B) head vertical | 4.71mt | 5.84mt | 5.37mt | 6.79mt | 6.13mt | 7.89mt |

| Max height (C) head vertical | 6.09mt | 7.01mt | 6.73mt | 7.90mt | 7.09mt | 8.35mt |

| Max height (D) head horizontal | 5.08mt | 5.99mt | 5.72mt | 6.89mt | 6.11mt | 7.38mt |

| Max reach (E) downwards | 3.05mt | 4.22mt | 3.68mt | 5.16mt | 4.29mt | 6.09mt |

| Min siding width (F) to tank | 2.29mt | N/R | 2.24mt | N/R | 2.24mt | N/R |

| Min siding width (G) to centre | 1.33mt | N/R | 1.28mt | N/R | 1.28mt | N/R |

| Height (H) to pivot | 1.55mt | 1.55mt | 1.55mt | 1.55mt | 1.55mt | 1.55mt |

|

All dimensions above with 1.2mt head

|

||||||

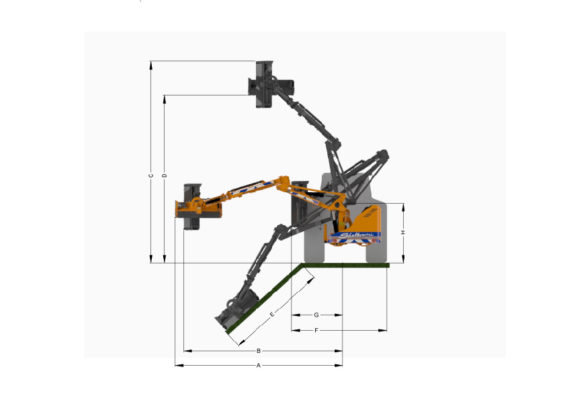

| REACH DIMENSIONS | 8065 VFRT | |||||

|---|---|---|---|---|---|---|

| Retracted | Extended | |||||

| Forward | Straight | Back | Forward | Straight | Back | |

| Max reach (A) head horizontal | 4.75 | 5.32 | 5.1 | 5.29 | 6.16 | 5.84 |

| Max reach (B) head vertical | 4.61 | 5.17 | 4.96 | 5.15 | 6.02 | 5.7 |

| Max height (C) head vertical | 5.86 | 6.28 | 6.12 | 6.3 | 6.93 | 6.69 |

| Max height (D) head horizontal | 4.81 | 5.24 | 5.08 | 5.25 | 5.88 | 5.65 |

| Max reach (E) downwards | - | 3.51 | - | - | 4.36 | - |

| Min siding width (F) to tank | - | 2.21 | 2.17 | - | - | - |

| Min siding width (G) to centre | - | 1.25 | 1.2 | - | - | - |

| Height (H) to pivot | 1.55 | 1.55 | 1.55 | 1.55 | 1.55 | 1.55 |

|

All dimensions above with 1.2mt head

8065 VFRT 1.38m forward & 0.89m back (Retracted) 2.00m forward 1.31m back (Extended) |

||||||

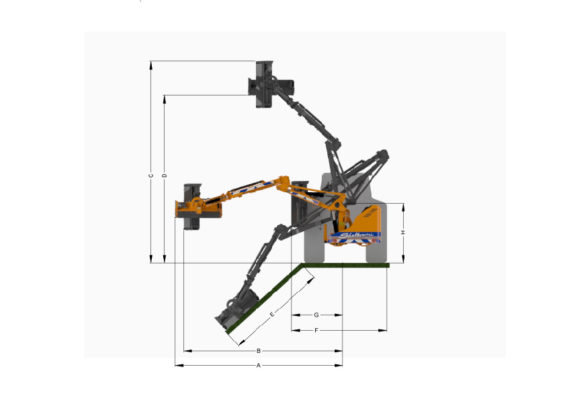

| REACH DIMENSIONS | 8075 VFRT | |||||

|---|---|---|---|---|---|---|

| Retracted | Extended | |||||

| Forward | Straight | Back | Forward | Straight | Back | |

| Max reach (A) head horizontal | 5.21 | 5.88 | 5.64 | 6.02 | 7.06 | 6.68 |

| Max reach (B) head vertical | 5.08 | 5.75 | 5.5 | 5.88 | 6.93 | 6.54 |

| Max height (C) head vertical | 6.44 | 6.73 | 6.56 | 6.53 | 7.12 | 6.9 |

| Max height (D) head horizontal | 5.07 | 5.45 | 5.31 | 5.53 | 6.08 | 5.9 |

| Max reach (E) downwards | - | 3.83 | - | - | 4.94 | - |

| Min siding width (F) to tank | - | 2.26 | 2.16 | - | - | - |

| Min siding width (G) to centre | - | 1.3 | 1.19 | - | - | - |

| Height (H) to pivot | 1.55 | 1.55 | 1.55 | 1.55 | 1.55 | 1.55 |

|

All dimensions above with 1.2mt head

8075 VFRT 1.6m forward & 1.03m back (Retracted) 2.47m forward 1.6m back (Extended) |

||||||

Looking for something specific?

Search our support area for individual model set-up guides and more...

All 8000 trimmers are recommended to be fitted with Axle mounting system however it’s possible to mount using 4 point linkage system.

Yes, the flails are arranged in a double spiral which gives a better cut finish and ejects significantly less debris to the side

No, the lower link arms are connected to the trimmer and used to take the weight before the axle bracket sub frame is engaged

The standard system produces 70HP using Shelbourne high pressure hydraulic system on all 7000 & 8000 Series, an 85HP hydraulic system is optional extra

All 8000 series machines are specified with durable drop forged flails as standard, these are available in either “T” or Competition configuration

Since 1972, Keith Shelbourne formed Shelbourne Reynolds Engineering Ltd, designing and manufacturing farm machinery in Suffolk, England.

Read moreBy: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds