If you have questions or require advice about the Stripper Header, or any of our other products, then contact us today.

WE ARE HIRING!If you're interested in building a career at Shelbourne Reynolds, then we want to hear from you.View our vacancies

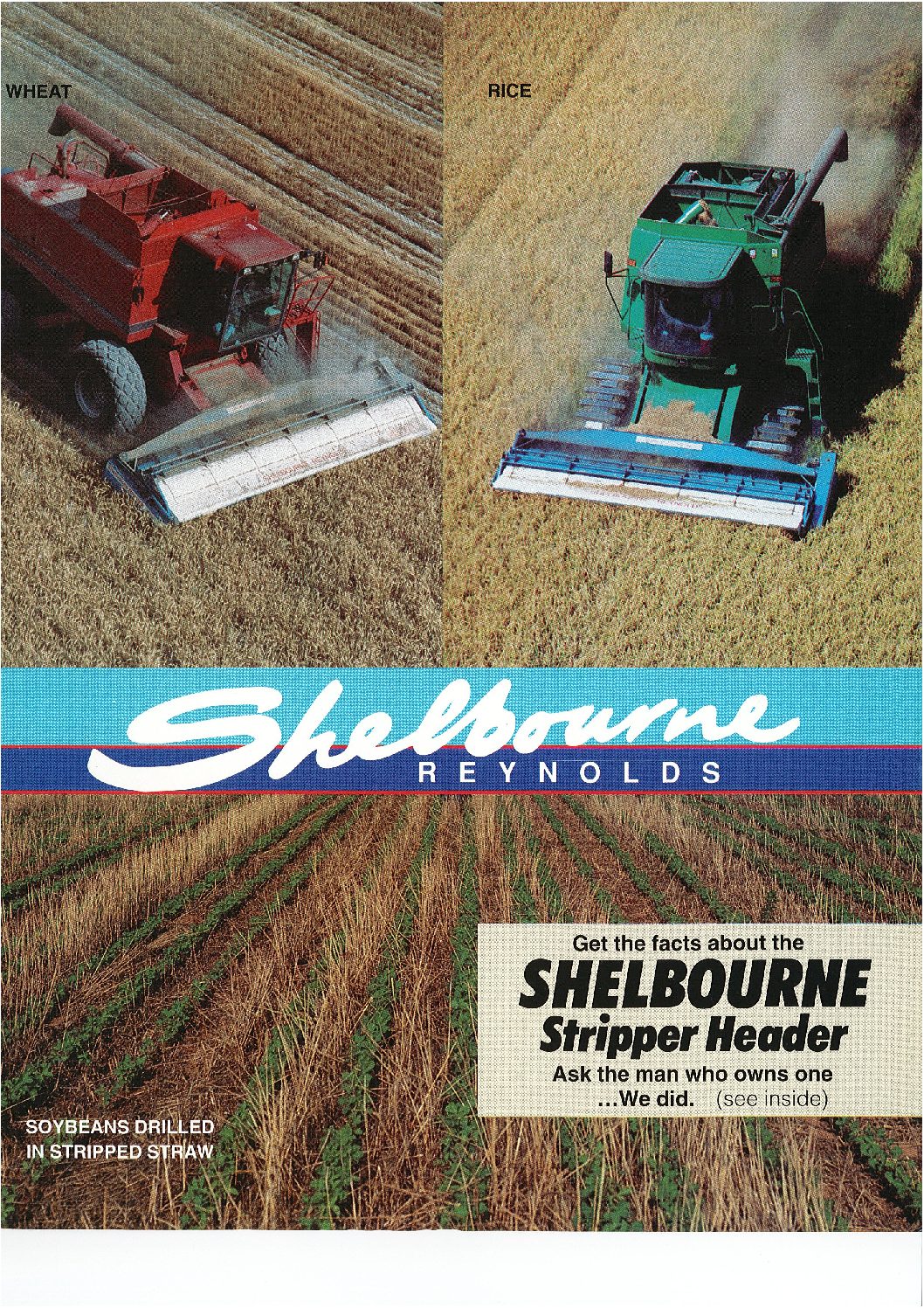

The stripper header is uniquely designed for a combine, it features a rotating stripping rotor with eight rows of stripping fingers that strip the grain or seed from the crop leaving the plant stem standing and attached to the ground.

The most important questions to ask when deciding on a model of stripper header for your operation are. What crop types do you want to harvest? and what combine size / type will the stripper header be mounted to?

The basic concept of the stripper header is that a rotating rotor fitted in the front of the header is fitted with 8 rows of stripping fingers that strip grain from the crop as the combine moves the head forwards while it spins backwards.

After the grain has been stripped by the rotor a series of deflectors within the header deflect the grain back into a conventional auger and pan.

This auger then moves the material to the centre where it enters the feederhouse of the combine. 85% of the grain is threshed by the header meaning that the material entering the combine is predominantly grain, chaff, leaf and minimal straw.

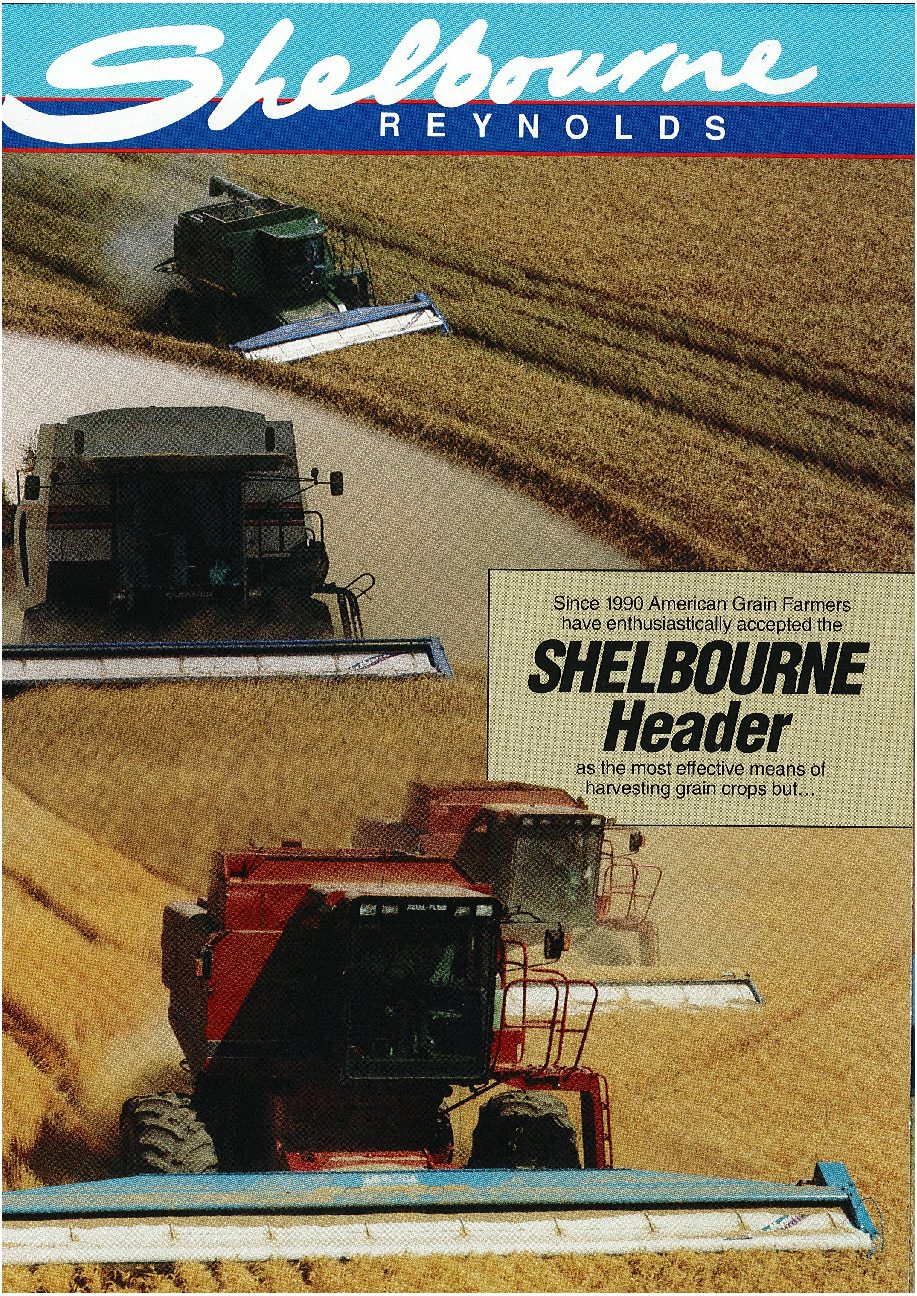

The Shelbourne Stripper Header is a unique and innovative product, Shelbourne Reynolds is committed to constantly improving and updating it, making the header more appealing to a wider range of customers and crops around the world. Re-sale value is excellent and people are constantly coming up with new uses for the headers.

The 18 foot SR5400 and 20 foot SR6000 were by far the most popular models built. The machine was designed for use in both wheat and rice. The cross sectional diagram below shows that the rotor feeds the crop back onto draper belts which then feed the material back to an uncovered auger.

The SR was a very successful model and most of the original machines are still in the field today. A strong demand for a wider machine as well as customer concerns over the durability of the draper belts (mostly due to rodent damage incurred over the winter) meant that the SR range was discontinued in 1994.

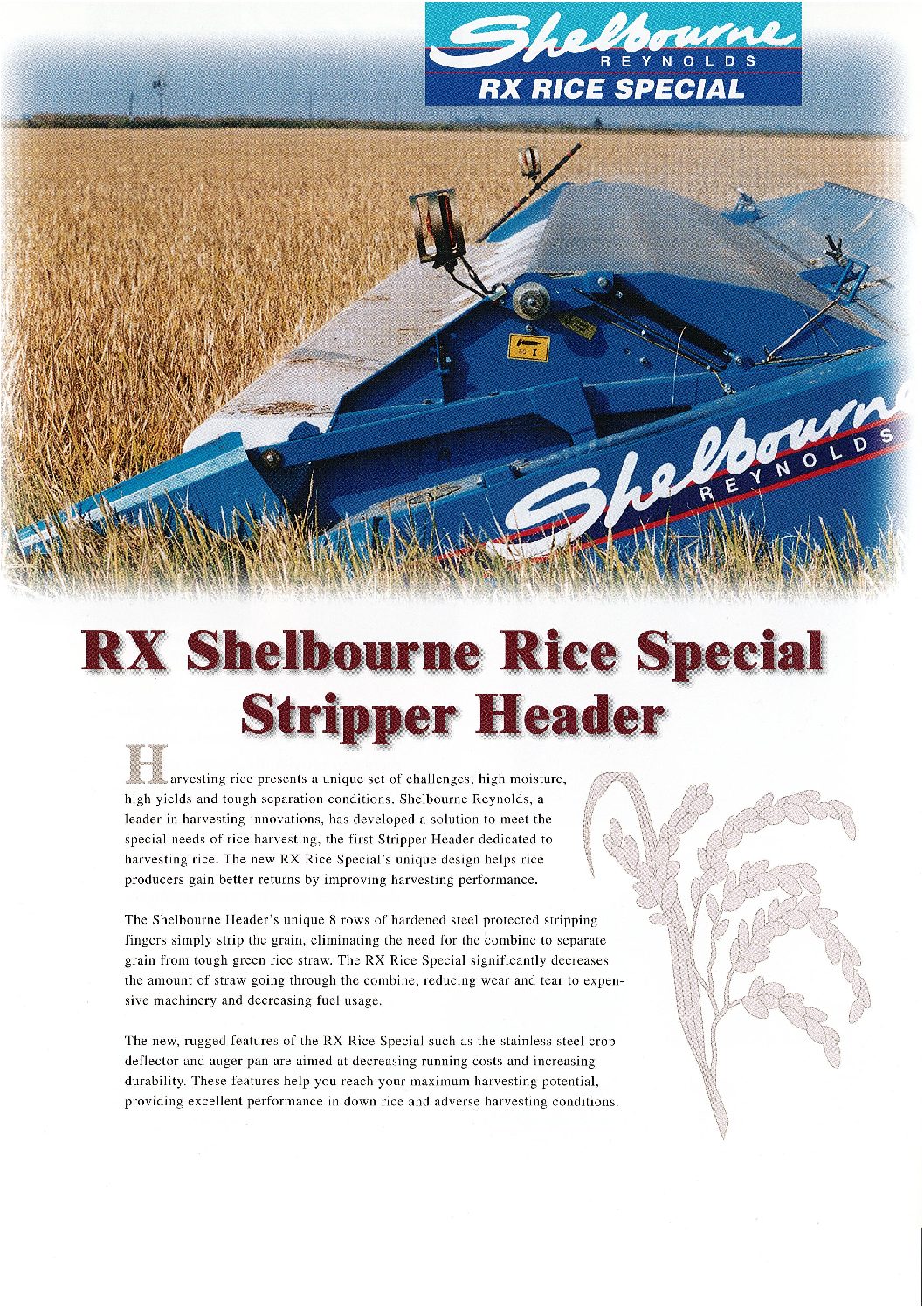

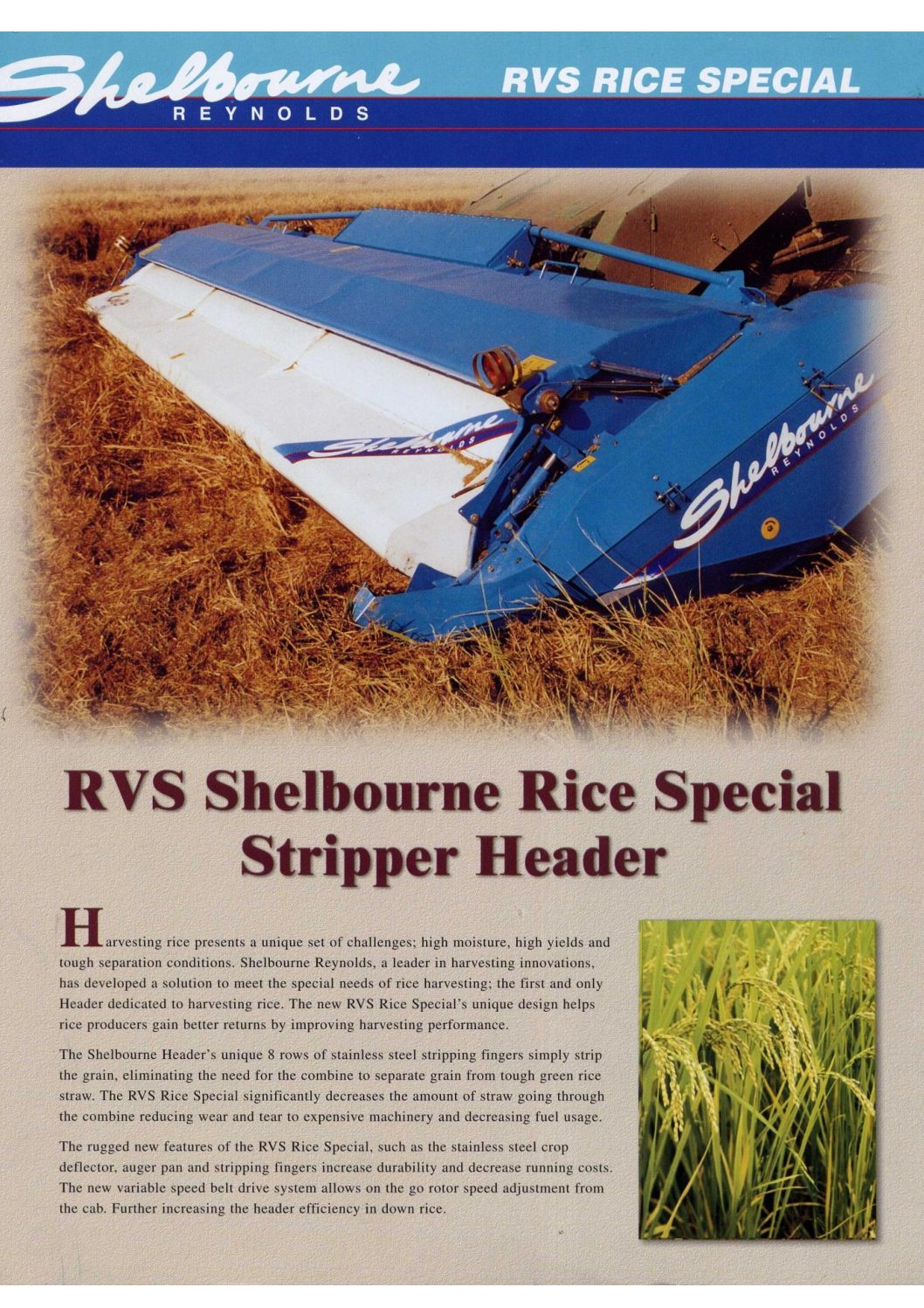

The RX was introduced as a dedicated rice header. A steel shaker pan replaced the conveyor belts as a means of transferring the wet heavy rice material from the stripping rotor to the auger. This design proved very successful and durable. 1999 Rice Special models featured many stainless and hardened steel components to extend their life expectancy and reduce the long term operating costs of the header. Stainless steel stripping fingers were fitted in 2000, these doubled the finger life expectancy as well as providing advantages in stripping performance.

The RX was produced until 2001 by which time it had gained a reputation as the header of choice if you were serious about harvesting rice.

The CX range was released in 1995 and was Shelbourne Reynolds first machine aimed at the US prairie wheat farmer. The CX84 (28 foot wide) machine was by far the most popular. The design was shortened from the SR and the rotor placed closer to the auger trough. Crop was moved directly from the rotor to the auger. This design worked very well in dry standing crop conditions although it had limitations when things became lodged damp or tough. These machines had the same gearbox drive as the SR range. Stainless steel "Seed Saver" stripping fingers were introduced in 1999 and were a major breakthrough in stripping tougher threshing wheat and durum varieties. When fitted with the cups orientated upwards the seed saver fingers enabled previously un-strippable varieties to be stripped with decreased loss.

The seed saver fingers can be fitted to any of the CX and RX models

The CX range was updated and improved annually until pressure for a variable speed rotor drive, still wider widths and better performance in tough conditions brought its production run to an end in 2000

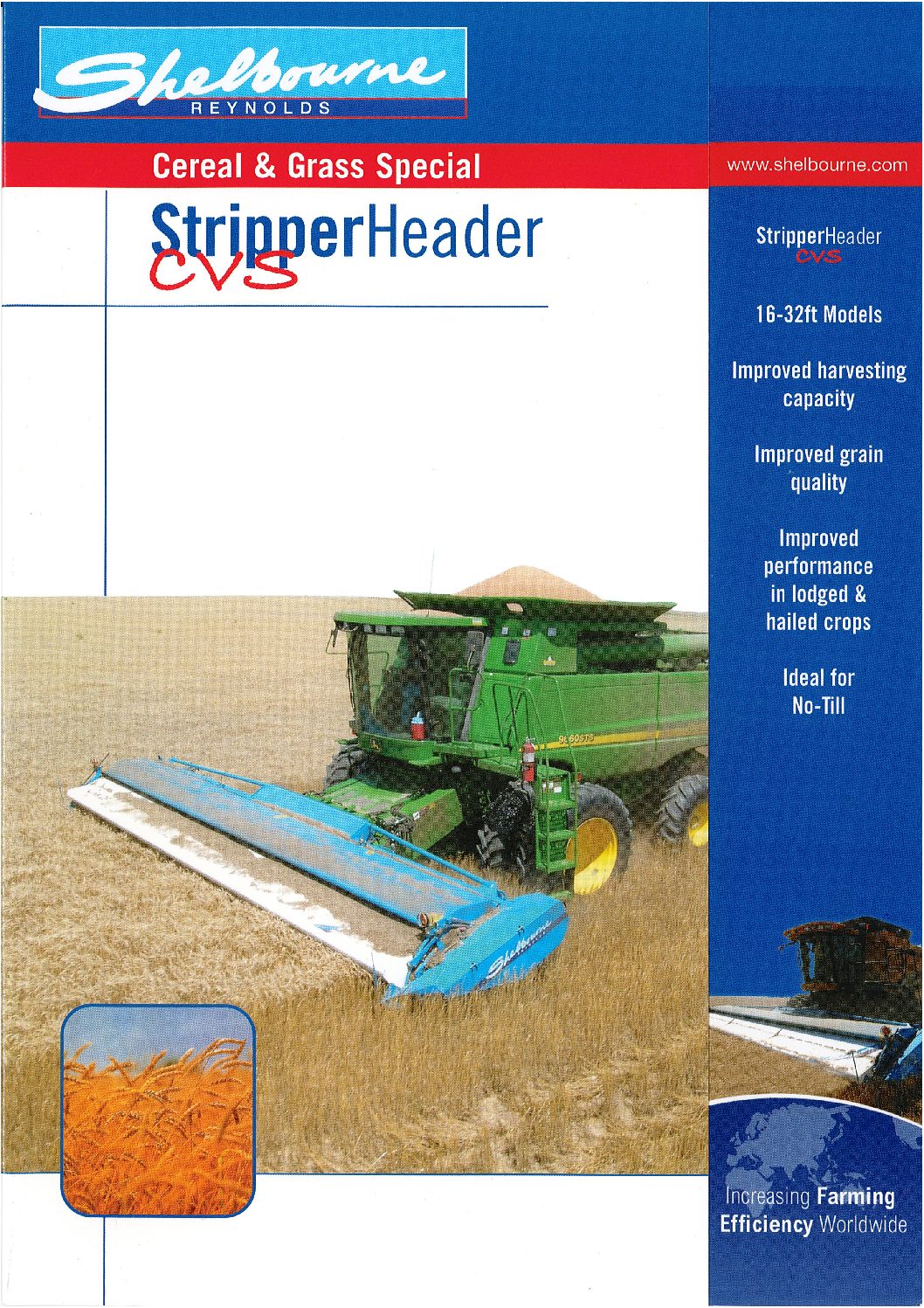

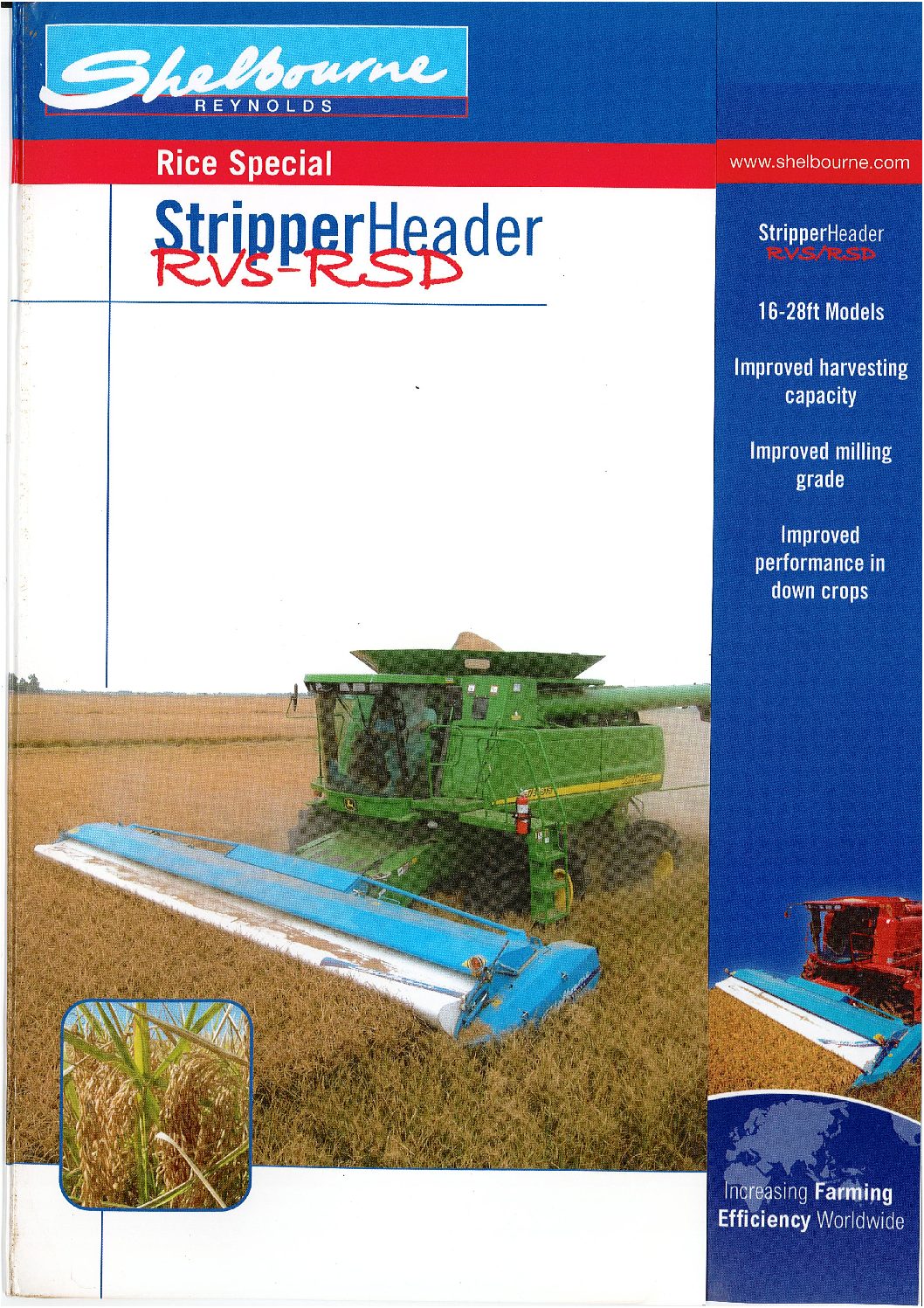

In 2000 after many years of testing and product development it was decided that both rice and cereals could be harvested with the same frame design with just relatively small design differences between ranges. The auger and rotor are placed closer together and grain is moved directly from the rotor to the auger. The deeper flighted larger diameter auger is able to handle more straw than before, this coupled with a larger shear bolt gives both these machines a significant advantage when harvesting lodged crops. A new variable speed drive system was developed which enables the operator to make rotor speed adjustments from the cab.

Extensive field testing proved that a deeper flighted auger sitting in a trough will feed better than a smaller one sitting on a flat pan. It is with this theory in mind the RX shaker pan machine was discontinued in favor of the direct feeding RVS header, this allowed the use of a common main frame with the CVS.

The Variable speed drive system was also introduced from the CVS model which allowed the operator to make rotor speed adjustments from the cab.

The RVS range features more stainless steel than on previous rice special models. The crop deflector, top hood and floor are stainless and the auger flighting and retractable auger fingers are made from hardened steel.

The RSD was developed using the existing RVS main frame incorporating a new drive system.

The fixed belt drive system offers a high level of consistent power to the rotor with minimal maintenance. It is therefore best suited to the tough harvesting conditions found in rice & grass seed where minimal adjustments of rotor speed are required.

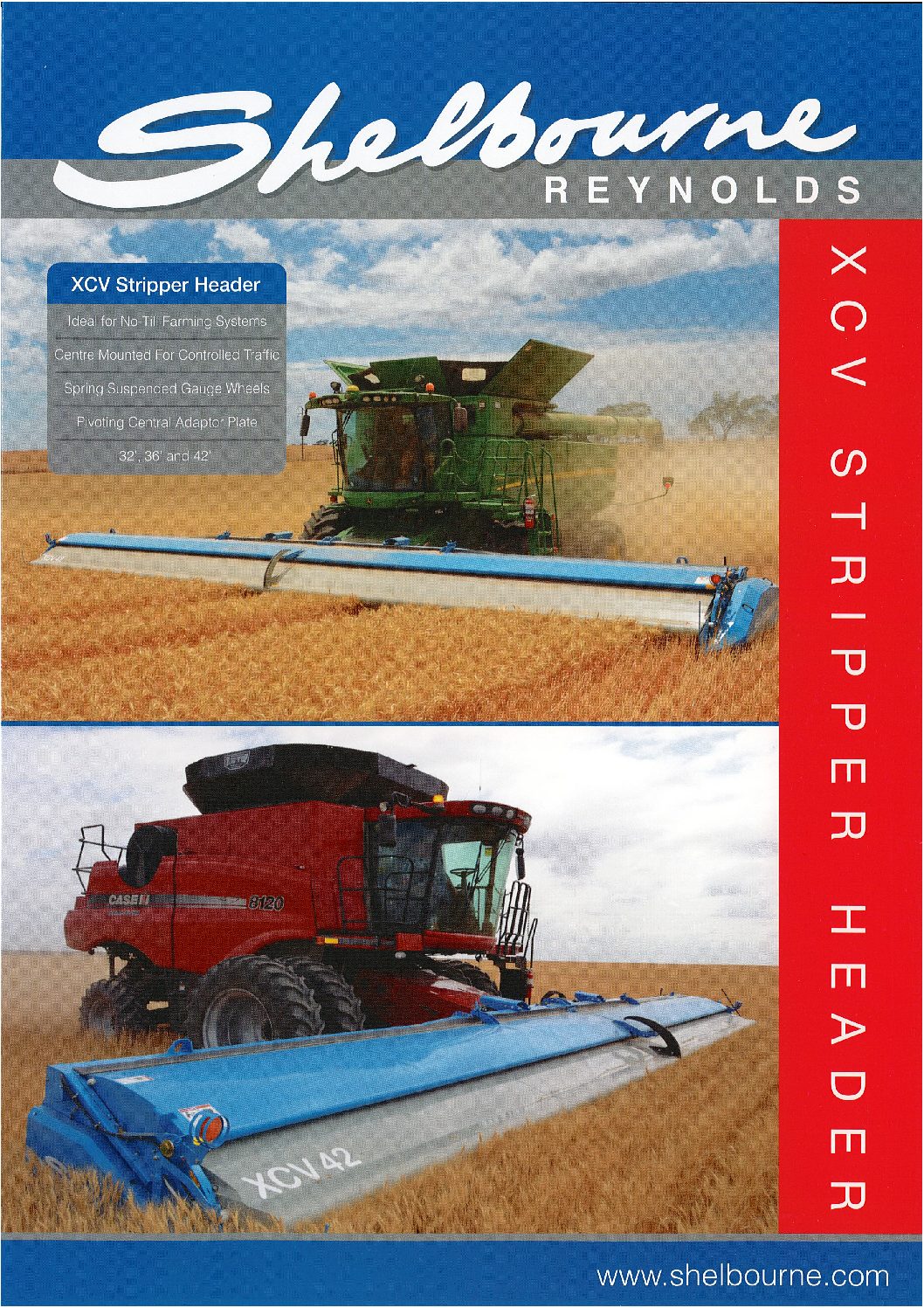

Larger capacity combines and larger scale farming prompted the development of the XCV range. The initial model was the XCV 42, this was then followed in 2014 with the XCV32 and XCV36.

The new machine incorporates 3 stripping rotors with two equally spaced division plates. A two piece auger is used with a central joint.

New features include a spring loaded pivoting adaptor plate and gauge wheels. All XCV machines are centre mounted on the combine feeder house.

If you have questions or require advice about the Stripper Header, or any of our other products, then contact us today.

Looking for something specific?

Search our support area for individual model set-up guides and more...

The auger is fitted with a slip clutch, this can slip if an excessive amount of straw is picked up at too high a ground speed.

The rotation of the rotor very successfully harvests crops lying on the ground because it has a picking up action.

Not really, the stripper head works by a rotary mechanical action rather than air flow.

No, the rotary action of the header is very gentle on the grain making the Shelbourne header popular with seed growers. The fact that most of the threshing is done in the header means that the threshing system of the combine can be slowed down to avoid grain damage, worst case scenario is over ripe soft wheat.

With combine engine speed at idle, engage the header drive and then the combine separator, causing the combine separator and the header to engage at the same time, reducing the snatch in the header drive line.

Please Click Here to download a document to explain an easy way to understanding your serial number. It is important to quote this number when ordering parts.

The CVS and XCV range of headers are equipped with a variable speed belt drive system enabling the operator to adjust the rotor speed using a cab mounted switch. The RSD the pulleys are swapped to give a different ratio.

You adjust the height of the crop deflector according to the height of the crop and then lower the whole header so that the crop gently brushes underneath the crop deflector.

The up-wards rotation of the rotor tends to kick rocks out in front rather than picking them up.

The rotating rotor mounted in the front of the header combs through the crop feeding the heads back into the keyhole area of the stripping finger where the grain is stripped from the head and thrown backwards into the header. The majority straw remains standing whilst the combine processes predominantly grain.

There is enough foreign material such as leaf and straw to enable it to feed up into the combine.

85% of the grain is threshed in the header, it will be necessary to set the combine a little differently in order to attain the normal 50 to 100% capacity increase associated with a Shelbourne header.

Winter wheat as a cover crop for soybeans is a little different for North Carolina farmers Darryl Corriher and Tom Hall. Cover crops are just one of several factors that allow the North Carolina...

For David Wagers, it just makes economic sense to use farming practices that stretch the meager rainfall eastern Colorado receives on an annual basis. The current seven years of drought the area...

Since 1972, Keith Shelbourne formed Shelbourne Reynolds Engineering Ltd, designing and manufacturing farm machinery in Suffolk, England.

Read moreBy: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds

By: Shelbourne Reynolds